Revolutionizing noise control with metamaterials is rapidly becoming a reality. These engineered materials offer superior soundproofing solutions, addressing the growing challenge of noise pollution that impacts our productivity, health, and well-being. Unlike traditional soundproofing methods, which often have limitations in efficiency and flexibility, metamaterials represent a cutting-edge innovation poised to redefine how we manage and control sound in various industries, from architecture to transportation and electronics.

Noise pollution is a pervasive problem in modern society, affecting our concentration, sleep quality, and even cardiovascular health.

Traditional solutions, like thick insulation or sound barriers, can be bulky, expensive, and often ineffective against low-frequency noise. Metamaterials present a revolutionary approach, offering a more effective and adaptable way to combat noise pollution.

What Are Metamaterials?

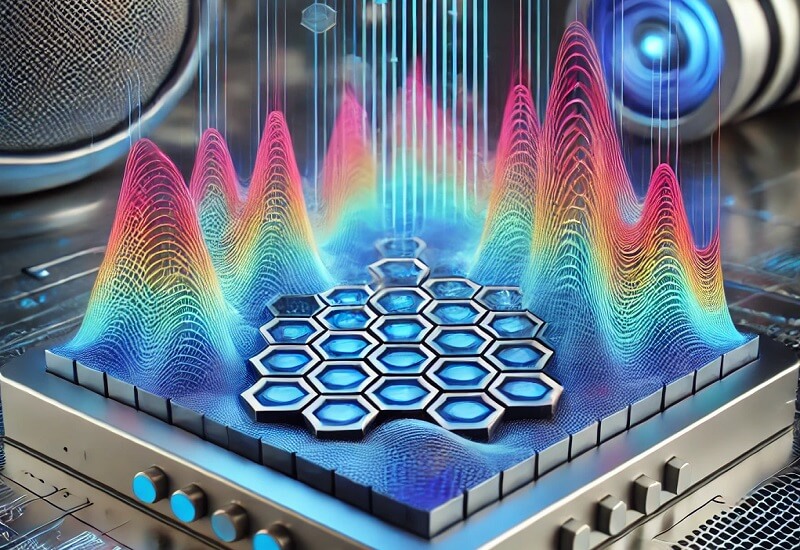

Metamaterials are artificially engineered materials designed with specific properties not found in nature. These properties stem from their intricate internal structures rather than their chemical composition.

This unique structural design allows them to interact with sound waves in unprecedented ways, enabling them to bend, absorb, or reflect sound with remarkable precision. For soundproofing applications, this means that metamaterials can be customized to target specific noise frequencies and provide superior sound insulation compared to conventional materials.

The ability of metamaterials to manipulate acoustic waves is rooted in their ability to exhibit unusual properties like negative mass density or negative modulus. While these properties don’t exist in naturally occurring materials, they can be achieved through careful design of the metamaterial’s structure.

For example, a metamaterial might consist of a network of tiny resonators, carefully arranged to interact with specific sound wavelengths. These properties enable unique interactions with sound waves, leading to significantly enhanced soundproofing capabilities.

How Metamaterials Work in Soundproofing

Manipulating Sound Waves

Metamaterials employ their unique structural design to influence sound waves in a variety of ways:

- Negative Mass Density: This counterintuitive property enables metamaterials to interact with sound waves in a way that effectively cancels them out, creating localized zones of reduced noise, often referred to as “quiet zones,” not complete silence.

This is achieved by designing structures that resonate out of phase with incoming sound waves.

- Wave Redirection: Metamaterials can bend and redirect sound waves around objects, similar to how light bends around a lens. This capability allows for effective sound insulation without the need for bulky and space-consuming materials. This redirection is achieved through carefully designed gradients in the metamaterial’s properties.

- Frequency Control: The engineered structures of metamaterials can be tailored to target specific frequency ranges.

This makes them ideal for tackling challenging noise types, like low-frequency sounds, which are difficult to control using traditional methods. This selective absorption or reflection of frequencies is achieved by tuning the resonant frequencies of the metamaterial’s structural elements.

Advanced Control

The precision with which metamaterials control acoustic energy makes them suitable for environments where traditional soundproofing methods fall short. For example, they can isolate low-frequency vibrations in heavy machinery, improving the work environment and reducing noise pollution.

They can also enhance speech clarity in crowded spaces such as auditoriums or conference halls by carefully manipulating the acoustic properties of the room.

Advantages of Metamaterials Over Traditional Soundproofing Materials

Lightweight Design

Metamaterials achieve exceptional soundproofing performance without the added weight and bulk of conventional solutions:

- Thinner Panels: Effective sound insulation can be achieved with significantly thinner panels compared to traditional materials like foam or fiberglass, saving space and weight.

- Portable Applications: Their lightweight nature makes them ideal for applications requiring portability, such as in the automotive and aerospace industries, where weight reduction is crucial for fuel efficiency.

Customization

The engineered nature of metamaterials allows for precise tailoring to specific needs and environments:

- Precision Engineering: The structure of a metamaterial can be precisely engineered to address a particular noise problem, offering a targeted approach to soundproofing.

- Versatile Applications: This customization makes metamaterials suitable for a wide range of applications across residential, industrial, and commercial settings.

Durability and Sustainability

Metamaterials often exhibit enhanced durability and reduced environmental impact compared to traditional options:

- Resilience: Metamaterials can maintain their performance over time, even in harsh conditions, providing long-lasting soundproofing solutions.

- Eco-Friendly Options: The design of metamaterials can incorporate recyclable or renewable materials, contributing to sustainable practices.

Applications of Metamaterials in Soundproofing

Architecture and Construction

Metamaterials offer innovative solutions for noise control in building design:

- Walls and Floors: Lightweight panels with high acoustic performance can be integrated into walls and floors to effectively minimize noise transmission between rooms or floors.

- Windows: Transparent metamaterials offer the potential for soundproofing windows without compromising natural light transmission.

Automotive and Transportation

The transportation sector benefits greatly from metamaterials’ noise reduction capabilities:

- Cars and Trucks: Quieter interiors enhance passenger comfort and reduce driver fatigue without adding significant weight to the vehicle.

- Airplanes: Lightweight metamaterials offer improved acoustic insulation in aircraft cabins while reducing fuel consumption due to lower weight.

Electronics and Appliances

Metamaterials are finding increasing use in consumer products:

- Household Devices: Integrating metamaterials into household appliances like washing machines and fans can significantly reduce their operating noise.

- Electronic Gadgets: Metamaterials can enhance sound quality in speakers and improve noise-canceling capabilities in headphones.

Medical and Industrial Use

Specialized environments benefit from the unique advantages of metamaterials:

- Hospitals: Metamaterials can provide enhanced soundproofing in sensitive areas such as MRI rooms, ensuring patient comfort and accurate readings.

- Factories: Reducing noise from heavy machinery with metamaterials improves worker safety, increases productivity, and minimizes noise pollution in surrounding communities.

Future Prospects of Metamaterials in Soundproofing

Emerging Technologies

Ongoing research and development are continuously expanding the capabilities of metamaterials:

- AI and Computational Design: Advanced algorithms are being used to optimize metamaterial properties for specific applications, leading to more effective and customized soundproofing solutions.

- Nanotechnology: The use of nanotechnology allows for the creation of even smaller and more intricate structures, pushing the boundaries of soundproofing capabilities at unprecedented scales.

Scalability and Commercial Viability

Metamaterials are transitioning from the realm of research to wider commercial application:

- Cost Reduction: Advancements in manufacturing techniques are making metamaterials more affordable and accessible for a wider range of applications.

- Mass Production: Techniques like 3D printing are enabling the large-scale production of metamaterials, paving the way for their broader adoption in various industries.

Expanding Applications

Metamaterials are poised to redefine noise control in diverse areas:

- Urban Planning: Integrating metamaterials into urban design can help reduce noise pollution in public spaces and transit systems, creating more livable and quieter cities.

- Smart Cities: Metamaterials can be integrated into adaptive sound management systems, dynamically adjusting to changing noise conditions in smart city environments.

Challenges and Limitations

Despite their immense potential, metamaterials face some challenges:

- High Development Costs: Designing and developing advanced metamaterials can require significant investment in research and specialized equipment.

- Material Availability: Some raw materials used in the fabrication of metamaterials might be scarce or expensive, potentially limiting their widespread adoption.

- Real-World Performance: Further research is necessary to fully understand and address the complex noise issues encountered in diverse real-world environments.

FAQ

What makes metamaterials better than traditional soundproofing materials?

Metamaterials offer a level of control over sound waves not possible with traditional materials. Their ability to manipulate sound waves allows for targeted noise reduction using lightweight and compact designs that outperform conventional soundproofing methods in many applications.

Can metamaterials address low-frequency noise?

Yes, metamaterials are particularly effective in managing low-frequency noise, a range often difficult to control using traditional methods like absorption or barriers.

Are metamaterials environmentally friendly?

Many metamaterials are being developed with sustainability in mind. Researchers and manufacturers are exploring the use of recyclable components and energy-efficient manufacturing processes to reduce their environmental impact.

Conclusion

Metamaterials represent a transformative advancement in soundproofing technology.

Their unique ability to manipulate sound waves opens up new possibilities for efficient, sustainable, and customizable noise control solutions. As research and development continue to overcome existing challenges, metamaterials have the potential to revolutionize various industries, creating quieter and more comfortable environments for everyone. The future of noise control is being shaped by the innovative potential of metamaterials.