In the pursuit of creating comfortable, functional, and aesthetically pleasing spaces, acoustic performance plays a vital role. Whether it’s a bustling office, a serene library, or a state-of-the-art concert hall, managing sound is crucial. While traditional acoustic panels have long served this purpose, they often fall short in design flexibility and sustainability.

3D printed acoustic panels offer a revolutionary solution, combining precision engineering, extensive customization options, and eco-friendly materials. This article explores how 3D printed acoustic panels enhance customization and performance, transforming the way we design and experience sound.

What Are 3D-Printed Acoustic Panels?

3D-printed acoustic panels are innovative sound management solutions crafted using additive manufacturing, commonly known as 3D printing. This process involves building a three-dimensional object layer by layer from a digital design.

Unlike traditional manufacturing methods that cut away material (subtractive manufacturing), additive manufacturing builds the panel up from a base material, allowing for intricate geometries and highly precise customization that would be difficult or impossible to achieve with traditional methods. This allows for intricate internal structures and external surface textures that can be precisely tuned to specific acoustic requirements, optimizing sound absorption, diffusion, and reflection.

The adaptability of 3D printing also extends to material selection, enabling the use of recycled plastics like PET, bio-based materials like PLA (polylactic acid) derived from cornstarch or sugarcane, and hybrid composites. This not only enhances acoustic performance but also aligns with sustainability objectives, making 3D-printed panels a preferred choice for environmentally conscious projects.

The Advantages of 3D-Printed Acoustic Panels

3D-printed acoustic panels offer a compelling combination of advantages that set them apart from traditional solutions.

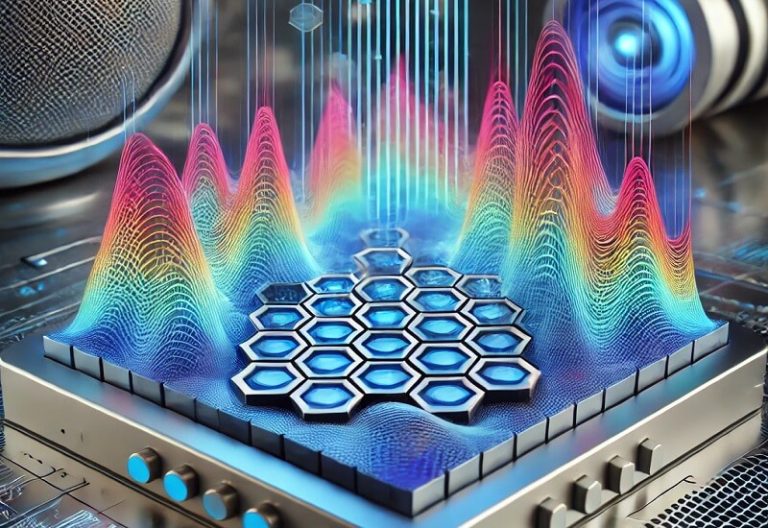

Their unparalleled customization allows for tailored designs to fit any room’s unique dimensions and acoustic needs, from small home theaters to large auditoriums. Complex geometries, such as honeycombs or fractals, can be incorporated to significantly improve sound diffusion and absorption. Designers can create visually appealing panels that seamlessly integrate with interior decor, serving as both functional and aesthetic elements.

The precision of 3D printing ensures each panel is produced to exact specifications, matching acoustic requirements and ensuring consistent performance.

This precision reduces variability and minimizes adjustments during installation, enhancing efficiency. The ability to precisely control the internal structure of the panel enables “frequency targeting” where the panel can be designed to absorb or diffuse specific frequency ranges, making them ideal for performance venues and recording studios where balanced acoustics are paramount.

Sustainability is also a core advantage. The use of recycled materials like PET (often from recycled plastic bottles) reduces waste and promotes circular economy principles.

Studies have shown that some 3D printed panels can incorporate up to 80% recycled content. Bio-based options, like PLA, provide a biodegradable alternative for projects prioritizing sustainability. Moreover, the additive manufacturing process generates minimal waste compared to subtractive methods, and often consumes less energy, leading to a lower carbon footprint.

How 3D Printing Enhances Acoustic Performance

3D printing enhances acoustic performance by enabling the creation of intricate internal geometries and surface textures tailored to specific sound management objectives.

Improved absorption is achieved through designs that effectively trap sound waves, reducing echo and reverberation. For example, a honeycomb structure creates a large surface area within the panel to absorb sound energy, particularly in mid-range frequencies. Enhanced diffusion is achieved through complex surface patterns, such as fractals, that scatter sound waves evenly across a space, preventing acoustic “dead spots” and ensuring a balanced listening experience.

Frequency targeting is accomplished by varying the panel’s internal structure and material properties. For instance, thicker, denser materials are better at absorbing lower frequencies, while lighter materials and complex shapes are more effective at diffusing higher frequencies. This level of control allows designers to achieve precise acoustic profiles for various applications.

Materials Used in 3D-Printed Acoustic Panels

Recycled Plastics

Recycled plastics, primarily PET, offer a sustainable and durable solution.

They contribute to a circular economy by diverting waste from landfills and often offer comparable acoustic performance to virgin materials.

Bio-Based Materials

Bio-based materials like PLA are derived from renewable resources like cornstarch or sugarcane. While offering a biodegradable alternative, PLA can be susceptible to moisture and temperature variations, limiting its applicability in certain environments.

Hybrid Materials

Hybrid materials combine natural fibers with polymers to create panels with enhanced properties, such as increased strength and flexibility. These materials offer a wider range of aesthetic options while providing good acoustic performance.

Applications of 3D-Printed Acoustic Panels

Commercial Spaces

In offices and conference rooms, 3D-printed panels reduce noise distractions and enhance speech intelligibility, fostering productivity and clear communication.

For instance, strategically placed panels can absorb reverberations from hard surfaces, minimizing background noise and improving the clarity of presentations.

Performance Venues

Concert halls, theaters, and recording studios benefit from the precise acoustic management offered by 3D-printed panels, optimizing sound quality for both performers and audiences. Custom-designed panels can fine-tune the reverberation time and frequency response of a space, enhancing clarity and ensuring an immersive auditory experience.

Residential Use

In homes, these panels provide soundproofing and aesthetic enhancement in home theaters, study rooms, and living spaces. They can effectively mitigate noise transfer between rooms and create quieter, more relaxing environments.

Educational Institutions

In classrooms and lecture halls, acoustic panels minimize background noise, enhancing learning comprehension and reducing distractions for students.

Challenges and Limitations

While advantageous, 3D-printed acoustic panels face challenges.

The initial investment in 3D printing equipment can be substantial, though costs decrease with scale and as technology advances. The availability of advanced sustainable materials varies regionally, potentially limiting material choices. Customization, while a significant benefit, can also limit mass production capabilities for large projects.

The cost-effectiveness compared to traditional panels depends on factors such as design complexity, material choices, and project scale.

Emerging Trends in 3D-Printed Acoustic Panels

The field of 3D-printed acoustics is constantly evolving. AI-driven design is being employed to optimize panel geometries for maximum acoustic efficiency, using algorithms to analyze sound behavior and generate optimal panel designs. IoT integration is enabling smart panels that monitor and adapt to real-time sound conditions, automatically adjusting their properties for optimal performance.

Multi-material printing allows the combination of different materials within a single panel, further enhancing functionality and durability.

FAQ

What are the main benefits of 3D-printed acoustic panels?

They offer precise customization, superior performance through advanced geometries, sustainability through material choices, and aesthetic flexibility, making them suitable for various applications.

Are 3D-printed acoustic panels eco-friendly?

Yes, they can be manufactured using recycled and bio-based materials, reducing waste and environmental impact compared to traditional methods.

Can 3D-printed panels match traditional options in performance?

Yes, and often surpass them, due to the ability to incorporate intricate designs tailored to specific acoustic needs and frequency ranges.

How much do 3D-printed acoustic panels cost?

The cost varies depending on size, design complexity, material choices, and quantity. While potentially higher upfront than mass-produced traditional options, customization and improved performance can offer long-term value.

How are 3D-printed acoustic panels installed?

Installation methods are similar to traditional panels and depend on the specific design and material. They can be mounted using adhesives, mechanical fasteners, or suspension systems.

Conclusion

3D-printed acoustic panels represent a significant advancement in sound management, merging innovation, sustainability, and high performance.

Their ability to provide customized solutions tailored to any space makes them a transformative tool in modern architecture and design. By adopting 3D-printed panels, architects and designers can achieve unparalleled acoustic quality while adhering to environmentally responsible practices. Exploring these cutting-edge solutions offers the opportunity to redefine the soundscape and enhance the experience of built environments.